Products & Solutions

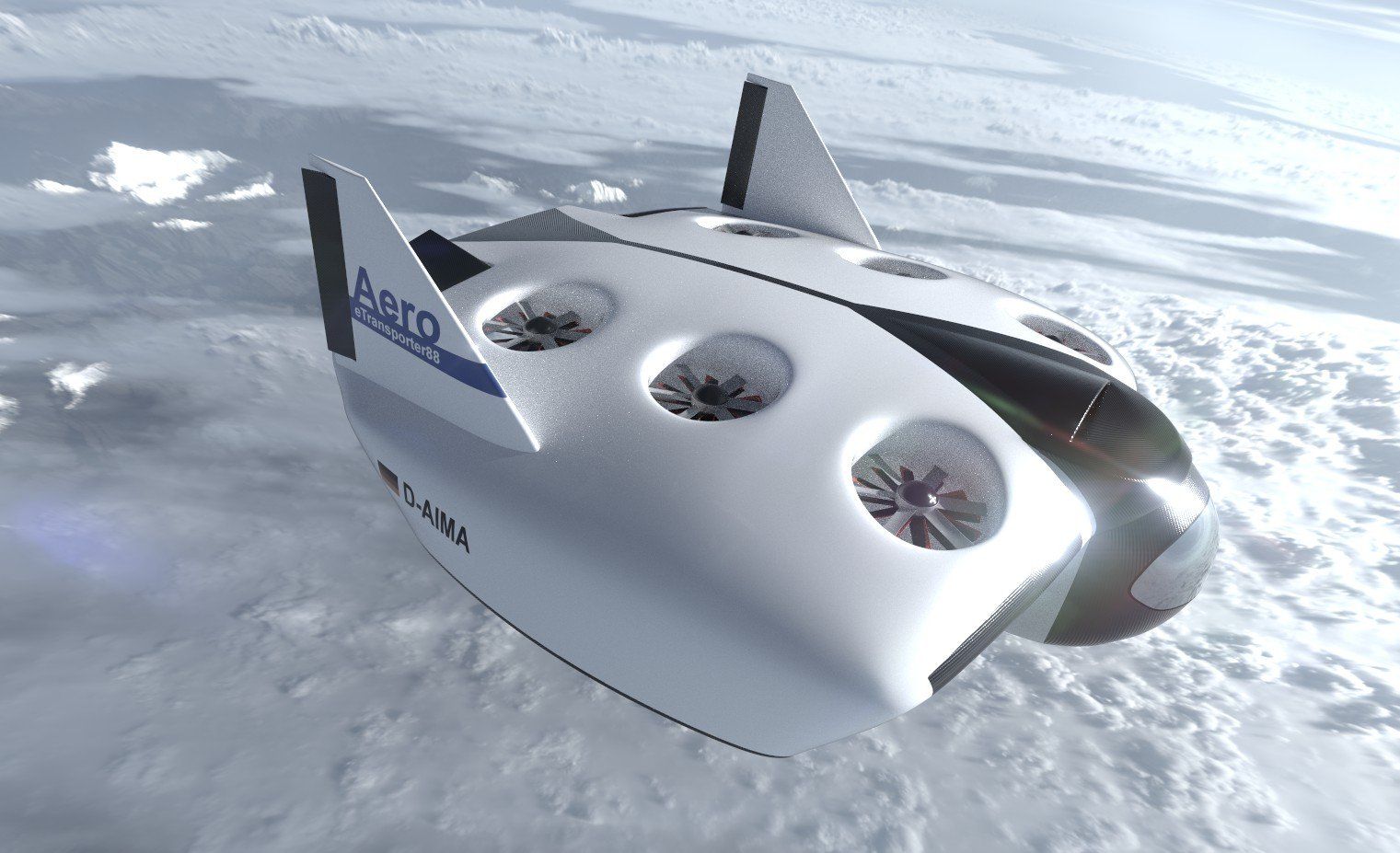

Combined Hybrid eVTOL

AeroTransporter-888

Range Extender

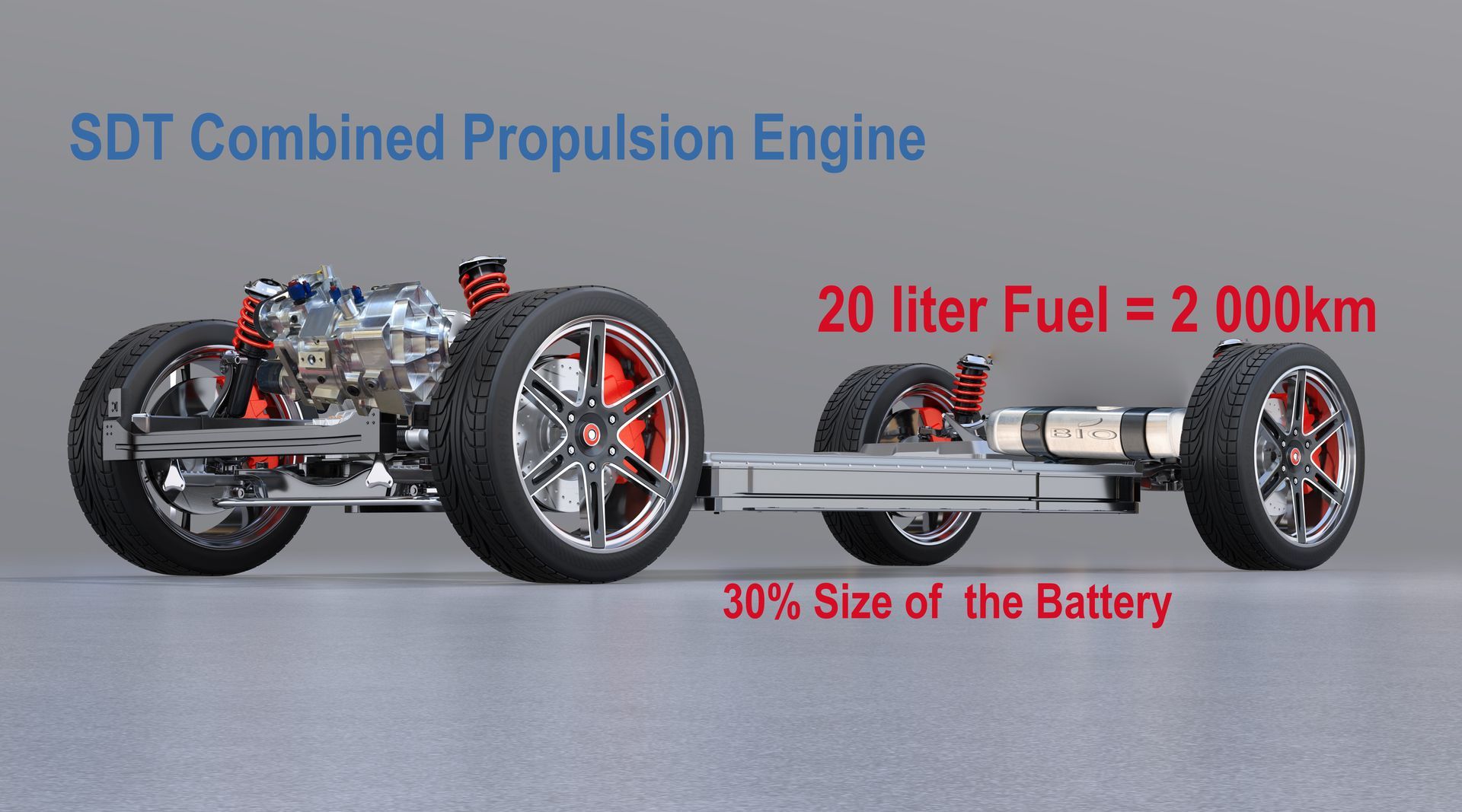

SDT Range Extender - Unlimited Mobility without Recharging over 2000 km

The electric vehicle manufacturers‘ range ratings often claim a range of up to 400 km to the nearest charging station, assuming a constant speed of 120 km/h under favorable conditions of 21°C outside temperature. However, additional variables such as low temperatures, winding roads with hills, and aggressive driving can significantly reduce range by up to 50% or more. While this may not be a very relevant issue for private users and vacationers, it becomes very crucial in critical scenarios such as emergency medical services, firefighting, freight logistics, and agricultural machinery.

This is precisely where the SDT combined propulsion solution enters the stage. This groundbreaking technology ensures an unequivocal travel range of up to 2000 km under the most diverse and taxing conditions. Even amidst freezing temperatures plummeting to -30°C and beyond, the SDT solution demonstrates steadfast reliability. The count of accelerations stands virtually boundless, and the performance retains unwavering stability even when the vehicle bears a considerable load.

The SDT solution constitutes a revolutionary innovation and harbors the potential to be a transformative force. It not only redefines the landscape of application possibilities for electric vehicles in demanding scenarios such as medical response, emergency firefighting, industrial hauling, and agricultural machinery, but it also sets novel ecological benchmarks compared to conventional all-electric propulsion systems.

Hence, the SDT combined propulsion solution isn‘t merely a solution for the quandaries of range and performance; it represents an eco-conscious departure from traditional propulsion paradigms. It serves as an inflection point in the evolutionary arc of electric mobility, articulating the symbiotic relationship between inventive progress and sustainability.

The Future is Now

The structure of the innovative SDT engine is quite simple: the exhaust gases from the internal combustion engine are directed into the mixing chamber of the power module, where they are mixed with fresh air from the air compressor driven by the internal combustion engine. The resulting gas-air mixture is supplied to a gas turbine connected to a drive shaft of an electric generator. This can be used to recharge the batteries and provide elect

rical power to the electric motors. The internal combustion engine is completely decoupled mechanically from the electric generator and the propulsion mechanism of the electric vehicle.

In this SDT Combined Engine, an internal combustion engine can operate within an optimal range of rotational speed and fuel consumption, without disruptive load fluctuations. The internal combustion engine operates at a constant speed range independent of the vehicle‘s motion since it is not mechanically involved in the vehicle‘s movement. Instead, it serves as a power source for recharging the batteries and supplying electrical power to the electric motors. As a result, the internal combustion engine is highly efficient, fuel-efficient, long-lasting, and also reduces noise and pollutant emissions.

During the operation of the SDT engine, the exhaust gases of the internal combustion engine release a significant portion of their thermal energy in the power module of the SDT engine to generate additional kinetic energy. After performing useful work and subsequent cleaning, the exhaust gas-air mixture is released into the atmosphere at a temperature close to ambient temperature. Returning to the bridging technology known as the „Range Extender“:

The SDT engine is used as a power generator to charge the batteries of the electric vehicle and supply the necessary electrical energy to the electric motors of the vehicle. This allows for a considerable range and reduces dependence on charging stations (and long charging times).

Theoretically, any electric vehicle equipped with an SDT engine can be refueled with diesel or gasoline at any conventional gas station in just a few minutes. With a full fuel tank of about 20 liters, it can provide comfortable electromobility with an outstanding range of over 2,000 km without the need for a stop at a battery charging station, with a remarkably low average fuel consumption of less then 1.4 liters per 100 km.

The realization of this SDT technical solution is based on the use of proven internal combustion engines (diesel or gasoline engines), as well as proven electric motors and available lithium-ion batteries.

The SDT engine should be considered as a bridging technology that can be utilized as an immediately deployable and safe technical solution. The scientific and technical developments underlying the SDT patent claims allow for the prompt implementation of relevant projects to expand mobility and promote the widespread adoption of electromobility.

Range extenders play a vital role in electromobility by mitigating range limitations, reducing charging infrastructure dependency, and providing a practical solution for drivers who require longer range capabilities. They contribute to the overall growth and acceptance of electric vehicles as a sustainable and viable transportation option.

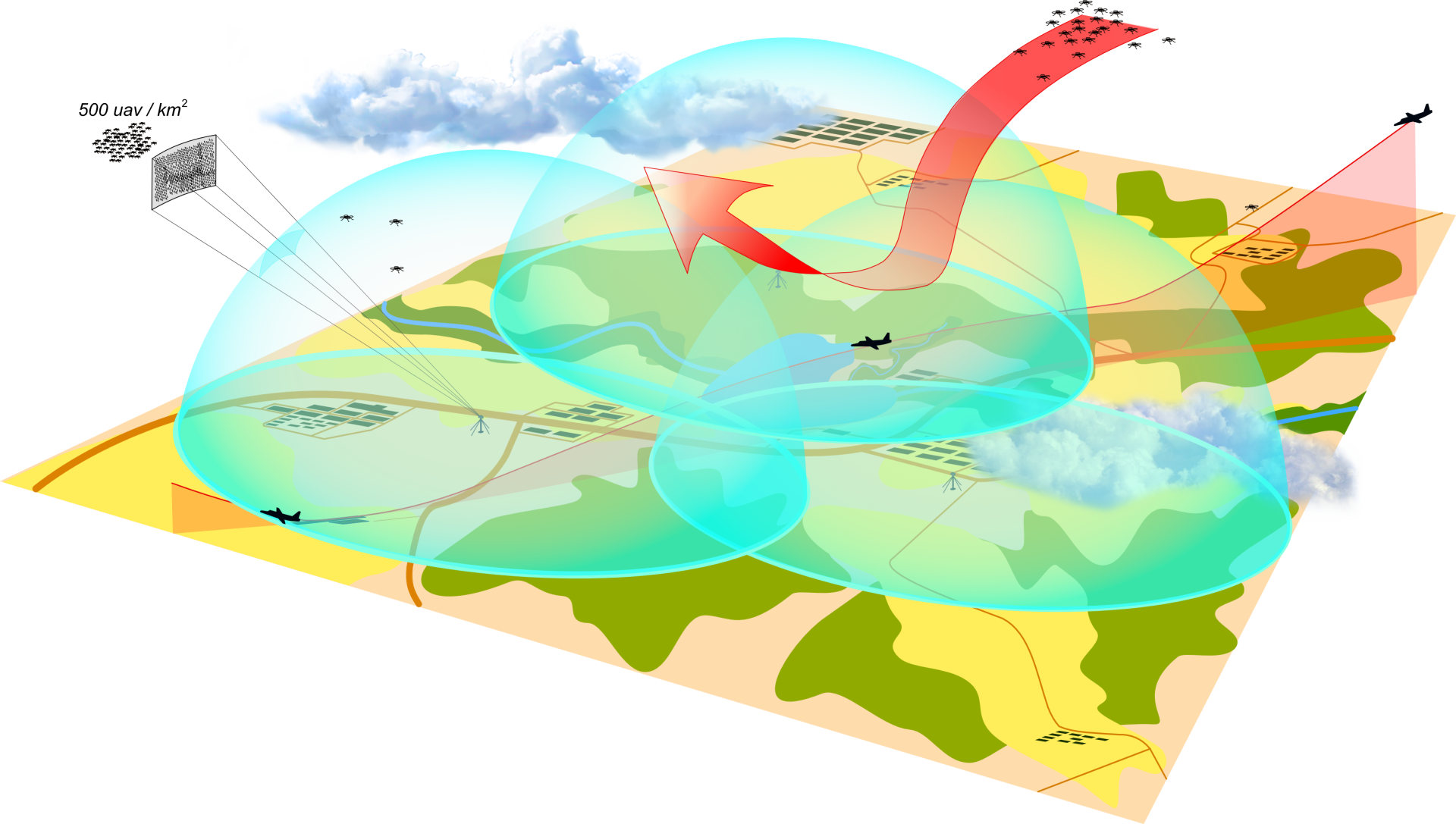

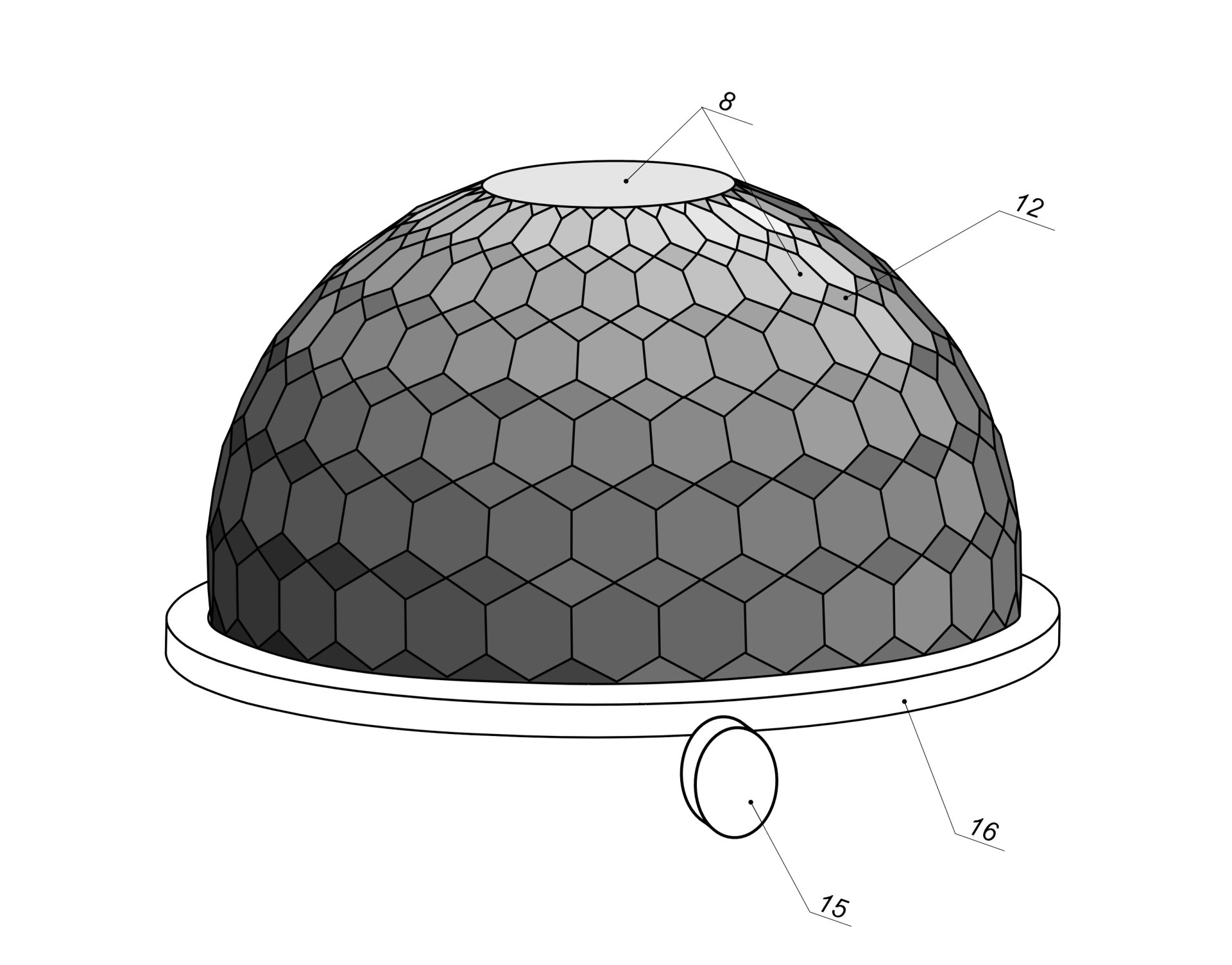

Drone Detection System

Optoelectronic Drone Detection System

Sphere-500

Introduction of commercial small UAS’s and UAV’s, which are known as Drones, changing drastically the world’s airspace situation and making them impossible to ignore. As their number rise, the importance of finding a way for them to safety coexist with manned aircraft growing dramatically.Drones operate mainly in low level airspace, an area with less regulations than the airspace occupied by manned aircraft. However, this may change, as the interest in recreational and commercial drone flights increases, prices drop, and technology advances. Beyond the initial usage for aerial video and photography, the use cases for drones are multiplying. For example, major retailers are investigating the possibility of using drones to make deliveries, farmers can use them to help manage large agricultural areas, and some emergency services use them to provide rapid medical intervention. The message is clear: drones have arrived, and they are here to stay. For aviation authorities across the world, the priority must be the full and safe integration of drone operations into existing aviation systems. This tremendous increase of Drones in the airspace has immediately raised security situation due to fact that these devices can intentionally or unintentionally cause serious hazards. In order to protect critical areas, many academic organization and industry did proposed several solutions in order to damp this critical situation. Present solutions allow to detect drones autonomously with use of RADAR, optical, acoustics and RF signal analysis, however all of them have critical for the airspace security limitations

The underlying SDT-Sphere 500 allows you to create airspace control stations on both mobile objects: eVTOL’s, UAV’s, helicopters and ground sites. This significantly expands the capabilities of providing a high level of flight safety, as well as creating airspace control systems taking into account the features of urban air mobility and regional air architecture.

Airspace Surveillance's and Search & Rescue System

Airspace Surveillance System

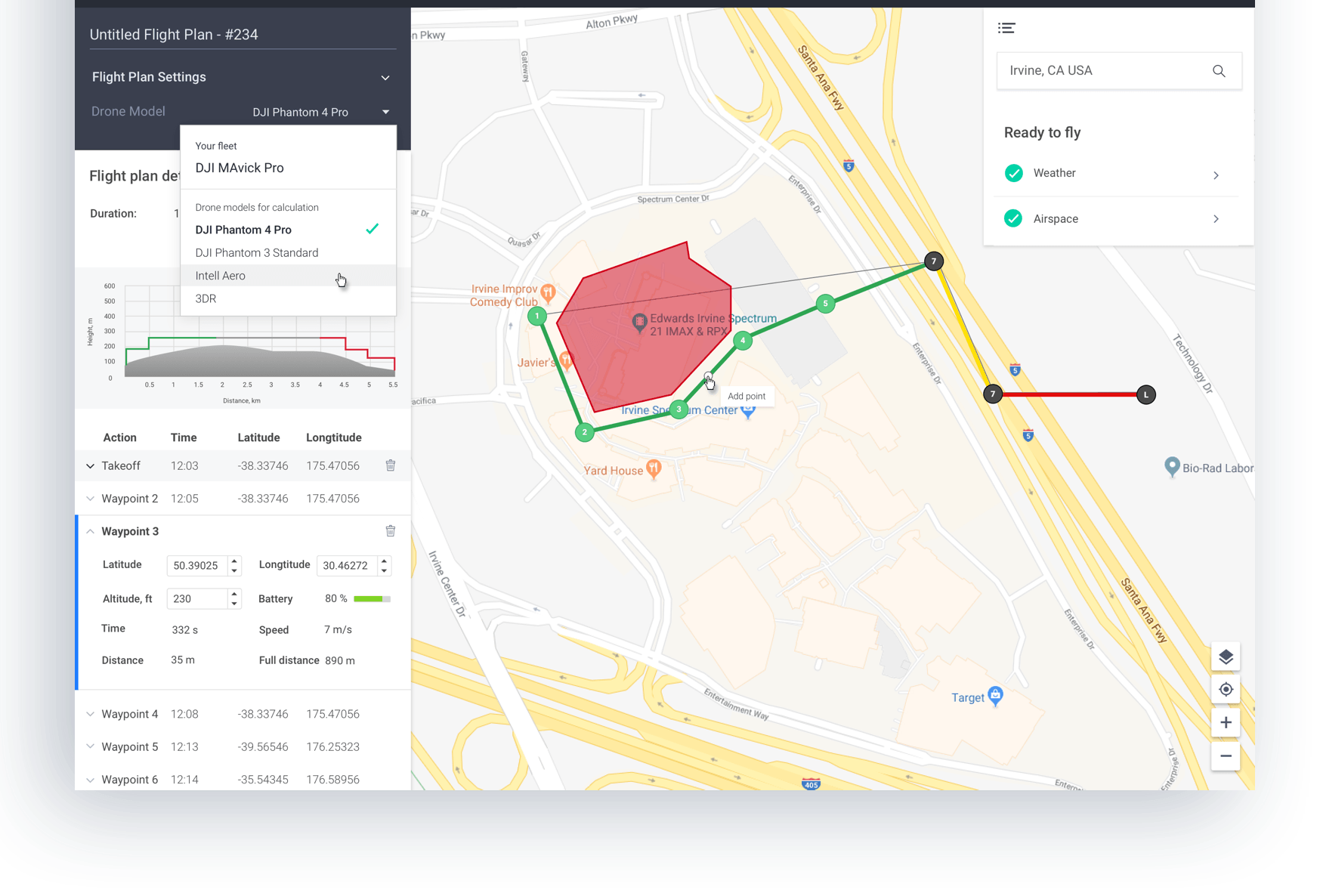

Falke 450

One of our projects is the development of the Falke450 unmanned aerial vehicle for a wide range of tasks: from searching for single small objects during search and rescue activities to surveying the Earth's surface for digital mapping. Feature of the UAV Falke 450 is the conformity of its functional indicators to solve problems and adaptation of the design to the logistics of its operation. For this purpose, its flight speed is increased up to 450 km/h and at the same time the probability of detection of a moving object is provided up to 0.9 against 0.3 - 0.35m for well-known UAVs.

Expansion of capabilities of the Falke 450 UAV became possible due to the implementation of modularity of design and operational replacement of the payload for the task: it can be an aerial camera, small radar, multispectral optical-electronic station or something else. To ensure the use of the Falke 450 UAV in mountainous conditions, a special laser station for measuring the slope range and current flight altitude is used as part of the aircraft. This proved to be very important for the countries of South-East Asia in creating a digital terrain map. A principal feature of the Falke 450 UAV is the application of a combined power unit based on a motor-drive unit based on a rotary piston engine and a single-stage axial compressor. Ceramic materials and interesting technical decisions have found wide application in its design that has allowed to reduce its weight almost on 30% and to bring between-repairs resource to 5 000 hours.

Laser Cutting Systems Dragon 1500

LCS Dragon 1500

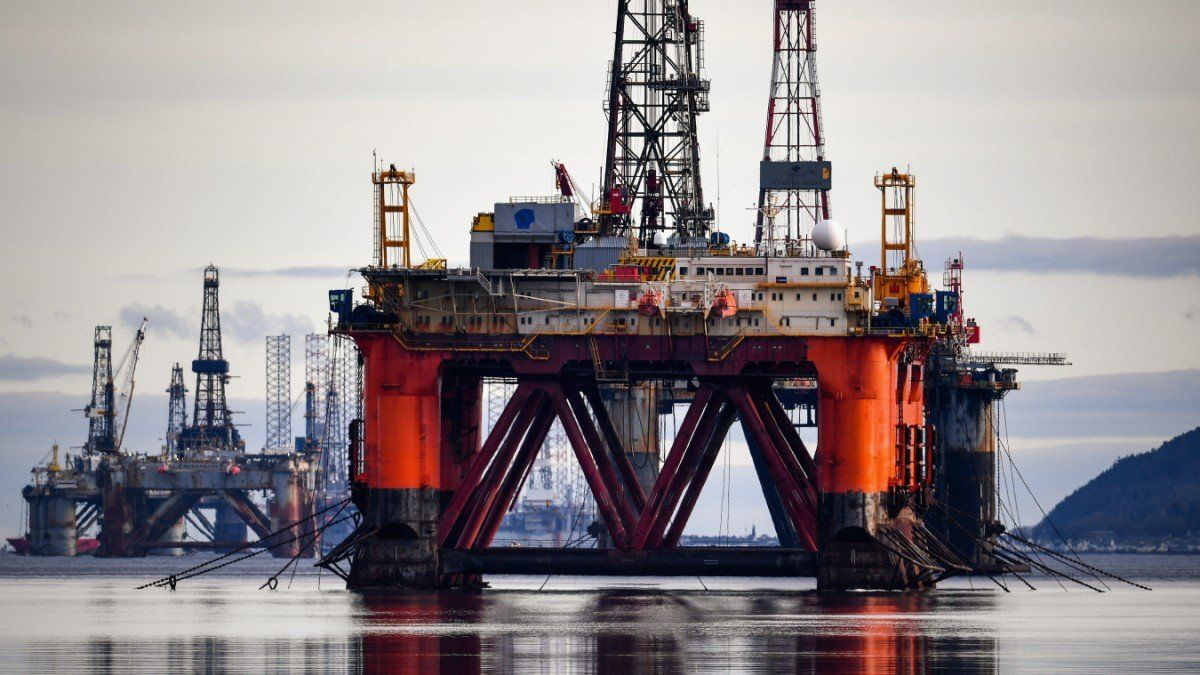

People's lives are connected with industry and energy. But there comes a time when infrastructural objects become obsolete or produce a resource. And then it becomes very difficult to dispose of these devices: it's expensive and not profitable at all. But it has to be done, otherwise the Earth will turn into a technological dump.

For this purpose, we are developing a special complex, which will allow unpleasant, not always clean and unsafe work to turn into high-tech and efficient activities. The demand for such a complex is best llustrated by figures: more than 2,000 oil and gas production derricks are waiting to be dismantled offshore.

There are more than a million abandoned factories and an enormous amount of scrap metal, often of high quality steel and non-ferrous metals, on state property; there are more than 10,000 wind turbines waiting to be dismantled.

Very often constructions that require cutting and dismantling are in hard-to- reach places, and the process of dismantling and disassembling can last from one month to a whole year and for this reason is unattractive organizational and economic activity.

The process of remotely cutting industrial structures is quite complex and requires high-tech equipment with the highest level of automation of technological operations. At the same time, for the safety of personnel and preservation of equipment, a distance of 100 meters to 1500 meters may be required between the remote laser cutting installation.

Very often special circumstances in the form of fire and adverse weather conditions, as well as contamination of the area, require prompt intervention to avoid catastrophic consequences.

The laser complex for remote structures is designed with the maximum number of all kinds of complexities and circumstances in mind.

The remote laser system is designed to meet as many challenges and opportunities as possible.

The remote laser system is designed for offshore and onshore applications, with a unique technology base and single technology for cutting structures.

A unified approach to creating a high performance laser remote cutting system is used for high mobility and responsiveness.

The laser complex has a block of laser heads, which allow to change the cutting modes of the structure in a very wide range of emitted energy.

There is a great opportunity to increase the power of radiation in operation, fast repair and modernization. Simultaneous cutting of three, two and one construction points is possible, including unstable position of the boards-mold. The operator can safely observe and control the entire cutting process.

Structural cutting is fully automatic, including job preparation and job monitoring.

Multiple cutting points, fast switching between them provides high cutting speeds and allows all available power to be concentrated in one point if necessary.

The complex uses highly reliable and

proven industrial sources of laser radiation, unique optoelectronic control devices and the latest advances in personnel safety and environmental protection.

Shipborne laser system is designed for laser cutting of technical spatial structures at a distance of 100 to 1,500 m. Structures can be located at sea and on shore. There can be different weather and climatic conditions, emissions of dense smoke, dust and open burning of oil and gas products.

It provides cutting of metal structures with wall thickness up to 80 mm at distance of 1,000 m with meteorological visibility range up to 10 km from dynamically unstable platform of small ship type with displacement up to 1,000 t under pitching conditions: keel, stern, course drift and their combinations in any proportion.

The particularity of the shipborne laser complex is the versatility of application in the form of use from various basic platforms:

maritime (river): ship, offshore platform, towed or self-propelled barge;

land: stationary, mobile car, mobile railroad.Neuer Text

The laser remote cutting system is designed for offshore and onshore applications, with a single technology platform and a single technology for cutting structures.

Air Disinfection System

Air Disinfection System LDA-2020

The device for air disinfection, is a comprehensive technical-scientific problem solving, a breakthrough innovation, for the significant containment of the spread of corona infection as well as pathogenic micro-flora and nano pathogens. The invention aims at significant decimation of potential pathogens, in particular virions/viruses on their main path of propagation, by means of large-volume and highly efficient technical-scientific respiratory air disinfection and, if necessary, sterilisation. A highly efficient disinfection of the breathing air is a highly effective and safe method for humans to combat the rapid spread of pathogenic germs. Our invention is specifically aimed at the containment of the spread of extracellular viruses/viruses. The invention makes the replication of the viruses and thus the infection of the host cells simply unlikely, since the spread of the viruses/virions is practically brought to an end. A patent application for the invention has been filed at the DPMA. Our invention is an innovative, highly efficient technical and scientific problem solution for current and future viral epidemics, irrespective of their peculiarities, strains and mutations.

The threatening spread of the Covid-19 has led us to a search for a solution to the problem. We regard the fight against the spread of the corona virus as the core of efficient problem solving.

We have taken the fundamental epidemiological principle of combating the spread of the corona virus as the basis for our technical and scientific invention.

In view of the high complexity of the virological processes involved in infecting humans and the high degree of ignorance of the manifold replication strategies and methods of the new Covid-19 and inability to counter the pandemic exclusively with virological means, it is plausible to limit the problem to the essentials - the spread of the virion before it enters the human cell seems plausible.

The essence of our invention is a comprehensive technical-scientific problem solution based on interdisciplinary knowledge from science and technology, which uses bio-physical and chemical processes to combat the viruses and bacteria in the air safely and efficiently.

The distribution path of Covid-19 is indisputable through the air we breathe. The risk of corona virus infection is given at a certain concentration of the viruses in a cubic meter. The special feature of Covid-19 for airborne distribution is its small size of approx. 10 nm (10x10/-9). The Covid-19 virus ion can transport the much larger dust particles in the air as a transport vehicle for further and longer air journeys to a putative host, the human being.