The rise of e-mobility has brought about significant advancements in transportation, promoting a greener and more sustainable future. However, the limited availability of energy and the short operating time of electric vehicles (EVs) and other e-mobility applications remain major challenges. This constraint has particularly critical implications for sectors such as maritime, aviation, and construction, where access to charging infrastructure is limited or even non-existent. SDT (Sustainable Design Team) presents a groundbreaking solution to extend the operational capabilities of e-vehicles and planes, allowing for enhanced and controlled usage in various applications.

The Energy Availability Limitation:

One of the primary concerns with e-mobility is the dependence on battery resources, which significantly affects the vehicle's or aircraft's operating time. The loads imposed on electric motors can quickly deplete the battery, resulting in a reduced working window. For instance, in certain demanding scenarios, fully loaded e-mobility platforms often have only a few minutes of operating time before the battery drains completely. This inherent limitation restricts the feasibility and practicality of using electric propulsion in critical applications.

SDT's Patent-Pending Solution:

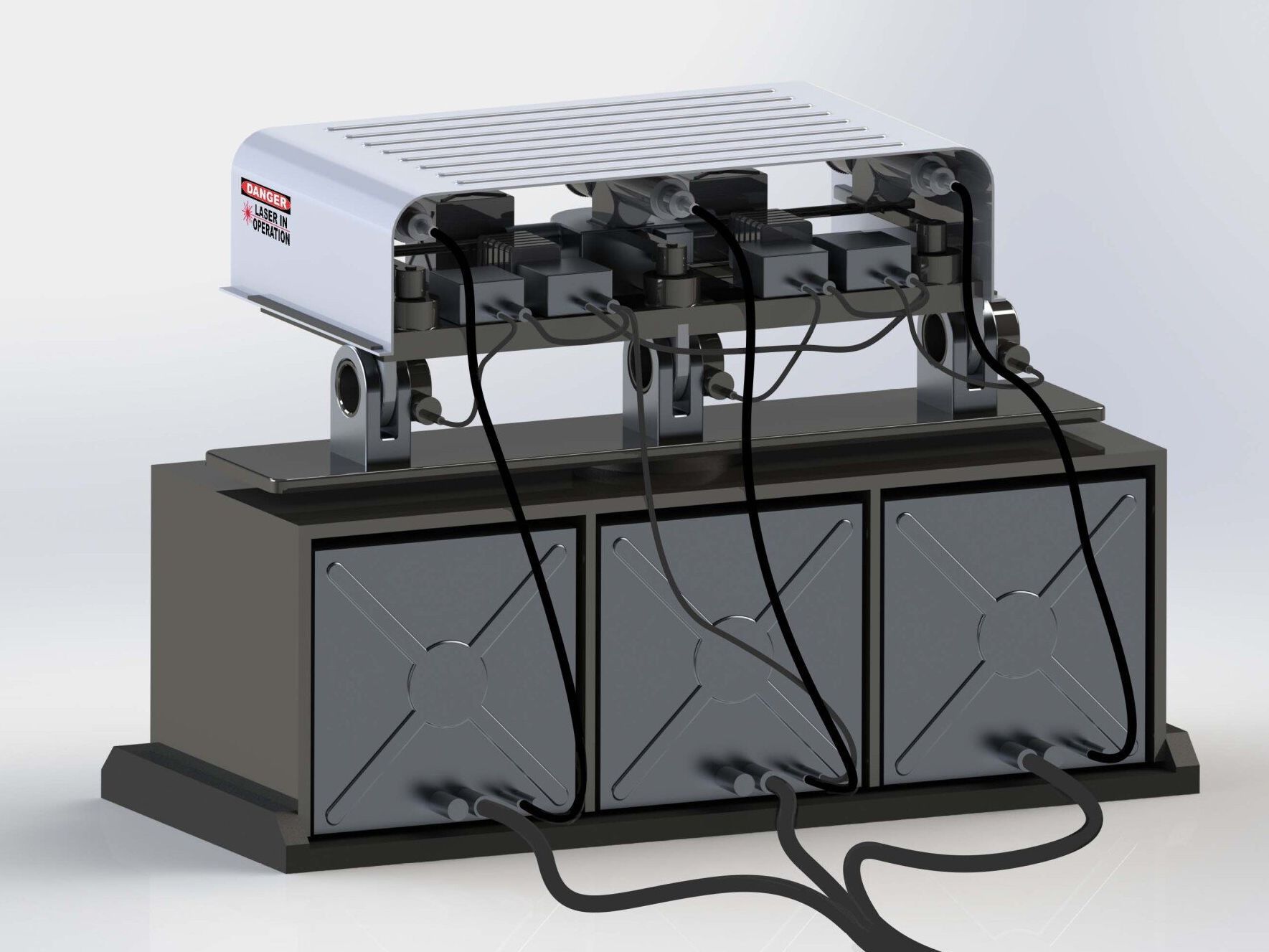

SDT has developed a proprietary technology that addresses the energy availability challenge in e-mobility. Their innovative solution, the SDT Combined Engine, incorporates a small on-board generator, revolutionizing the capabilities of e-vehicles and planes. By integrating this generator, SDT significantly reduces the required battery size by 50%, thereby mitigating the burden of battery weight. Surprisingly, this integration only adds a mere 25kg to the overall propulsion system, ensuring that the additional weight remains manageable.

Environmental Benefits:

Beyond the extension of operational time, SDT's technology also brings substantial environmental advantages. The SDT Combined Engine drastically minimizes the ecological footprint of e-mobility solutions. Notably, it achieves this by reducing emissions of CO2, NOX, and other exhaust gases to levels comparable to ambient temperatures. The exhaust gas temperature remains low, contributing to a safer and more sustainable operational environment. Additionally, the noise generated by SDT-powered systems is remarkably low, peaking at a maximum of 55 decibels. This reduction in noise pollution benefits not only passengers but also the surrounding communities.

Revolutionizing the eMobility Industry:

The implications of SDT's unique technology are far-reaching. By bridging the gap between energy limitations and operational demands, SDT is paving the way for a smoother transition to fully electric solutions. The capability to extend the operational time of e-vehicles and planes ensures enhanced performance, reliability, and safety. With SDT's revolutionary technology, sectors such as maritime transportation, aviation, and construction can now consider electric propulsion without the constraints of limited charging infrastructure.

Conclusion:

As the e-mobility industry continues to evolve, overcoming the limitations posed by energy availability is crucial. SDT's groundbreaking solution offers a paradigm shift in this domain. By integrating a small on-board generator, the SDT Combined Engine extends the operational capabilities of e-vehicles and planes, reducing the dependency on batteries and the associated weight burdens. Moreover, SDT's technology delivers exceptional environmental benefits, including significantly reduced emissions and noise levels. With SDT's innovation, the e-mobility industry can confidently embrace a greener future while ensuring optimal performance and addressing the challenges of energy availability.